Contact us

ADD:No. A06, Canda Entrepreneurship Counseling Base, Anping County, Hengshui City, Hebei Province,China

E-mail:sales@maituowiremesh.com

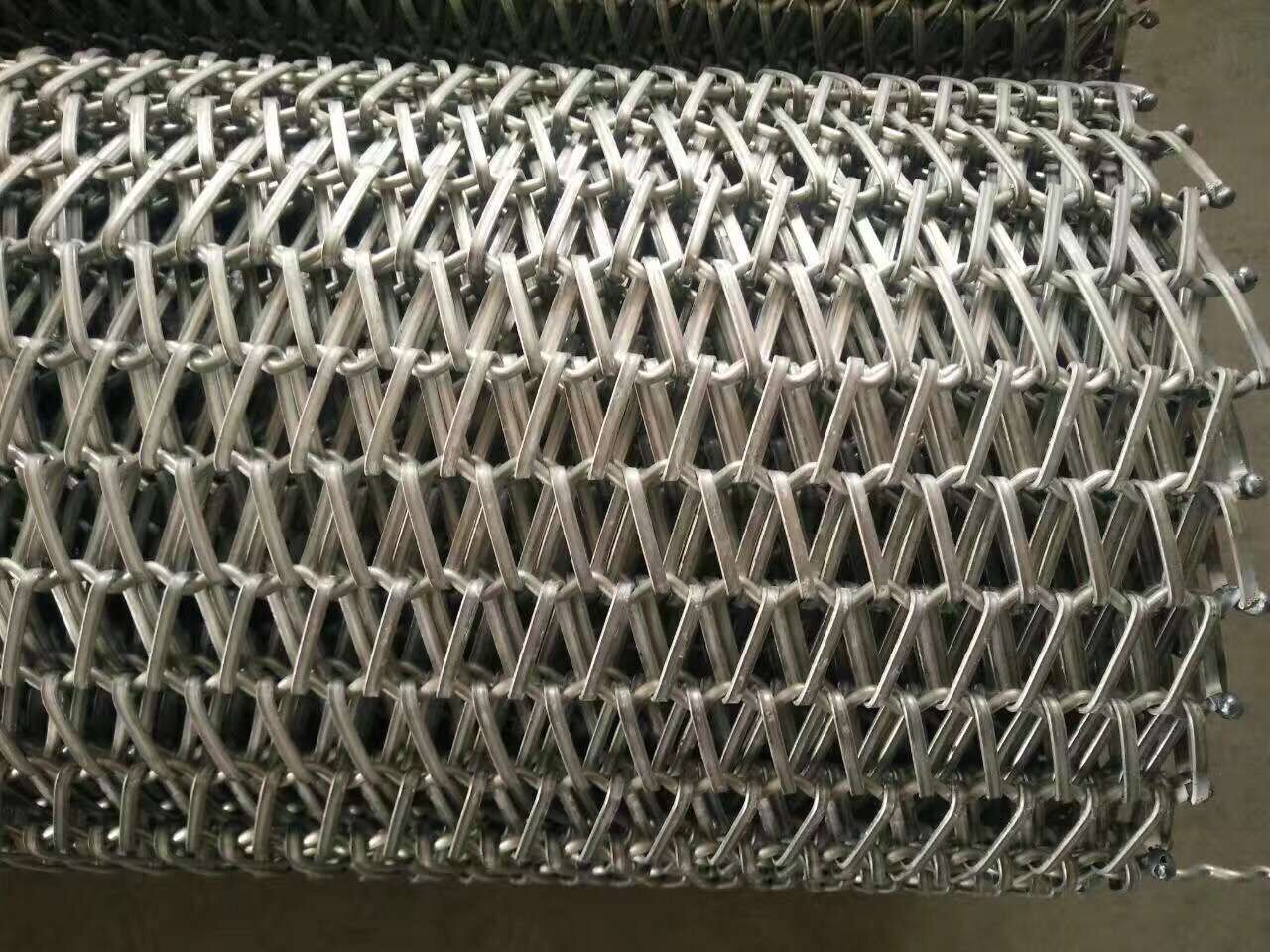

Spiral Link conveyor belt

Wide spiral conveyor belts have been successfully used in e.g. the food industry, the steel industry, the chemical industry and the glass industry for many years. Its simple design, the big range of dimensions (wire diameters and pitches) and the various ranges of belt materials are the main reason for its success.

Classification:

Metal conveyor belt

Keywords:

Whatsapp/Wechat/Tel:

Product description

Wide spiral conveyor belts have been successfully used in e.g. the food industry, the steel industry, the chemical industry and the glass industry for many years. Its simple design, the big range of dimensions (wire diameters and pitches) and the various ranges of belt materials are the main reason for its success.

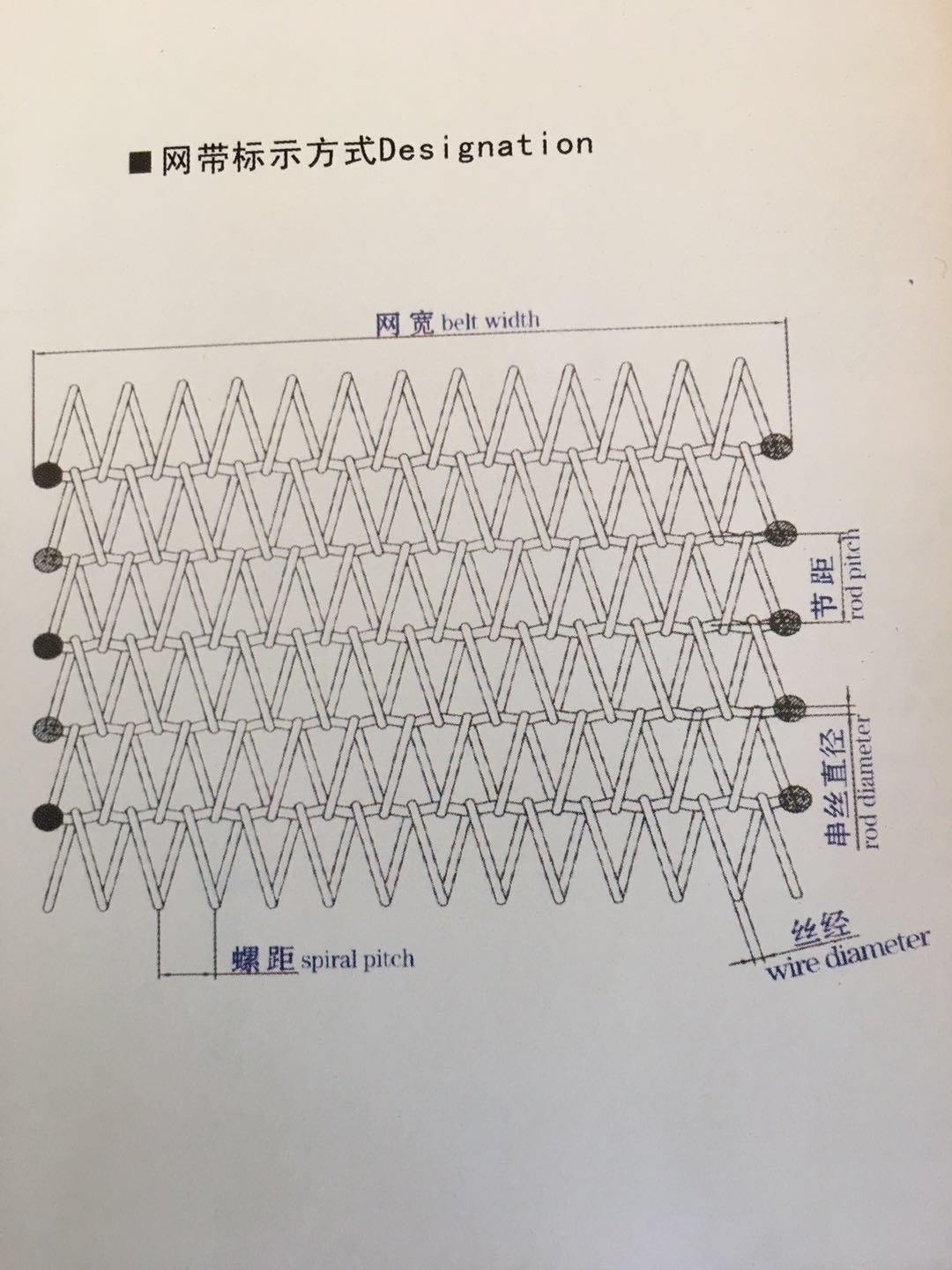

The wide spiral conveyor belt is a balanced woven belt with left and right hand wound spirals, connected by crimped cross wires. At the sides of the belt the cross wire is welded to the spiral wire.

The opening (‘drain’) of the wide spiral belt is determined by the pitch of the spirals and the pitch of the cross rods. The range of belts starts with a pitch of the spirals and pitch of the cross rods of 4 mm and goes up to pitches of 50 mm. The wire diameters can be chosen from 0,8 mm up to 5 mm but are in a way determined by the belt pitches too. Normally the belt has round wires, but can be executed with flattened wire as well.

Wide spiral belts can be used in a temperature range of -50º up to +1100ºC, and can be delivered in every length and belt width up to 4 meters or more.

For a very tight mesh the belt can be multiple woven or compound balanced. In this belt the spirals are nested and one spiral has 3 or 4 or 5 cross rods instead of 2.

Wide spiral belts can be executed with chains at both sides, with hollow pin chains or with solid pin chains. The connection between the chains and the belt is mostly by means of extra cross rods going through the (spiral of the) belt and trough the chains.

The spiral part of the belt will carry the product. The chains will drive and guide the spiral part. Driving this belt is easy by means of chain sprockets.

Wide spiral belts normally have to be driven, tension-ed and guided by means of plain rollers.

In many cases the position of the belt has to be controlled and one or more rollers are executed as dynamic steering rollers. Belt speeds from 0,5 m/min up to 60 m/min are possible.

Driving the Wide spiral belt with sprockets is possible in case of light products on small conveyor belts and a normal belt speed.

Wide spiral belts can on occasion be equipped with flights.

Wide spiral belts can be easily made endless by placing a crimped cross wire between a left hand wound and a right hand wound spiral and welding this crimped wire ends together with the spiral wire ends.

Wide spiral belts normally have to be driven, tension-ed and guided by means of plain rollers. In many cases the position of the belt has to be controlled and one or more rollers are executed as dynamic steering rollers. Belt speeds from 0,5 m/min up to 60 m/min are possible.

Driving the Wide spiral belt with sprockets is possible in case of light products on small conveyor belts and a normal belt speed.

Wide spiral belts can on occasion be equipped with flights.

Wide spiral belts can be easily made endless by placing a crimped cross wire between a left hand wound and a right hand

Previous

Previous

Product inquiry

We will contact you within one working day. Please pay attention to your email.