Contact us

ADD:No. A06, Canda Entrepreneurship Counseling Base, Anping County, Hengshui City, Hebei Province,China

E-mail:sales@maituowiremesh.com

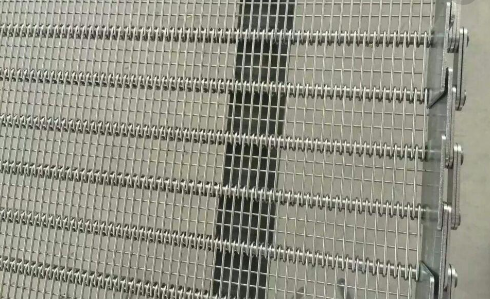

Eyelink conveyor belt

For many decades, our Wire Link Conveyor Belts, also named Eye-link Belts, have been successfully used in the food industry, the steel industry and the chemical industry. The reliability and durability of the belts are the main reason for its success, combined with the various ranges of belt materials and the sophisticated design, which makes it relatively simple to make variant types of belts.

Classification:

Metal conveyor belt

Keywords:

Whatsapp/Wechat/Tel:

Product description

For many decades, our Wire Link Conveyor Belts, also named Eye-link Belts, have been successfully used in the food industry, the steel industry and the chemical industry. The reliability and durability of the belts are the main reason for its success, combined with the various ranges of belt materials and the sophisticated design, which makes it relatively simple to make variant types of belts.

The opening between the wire links are tailor-made by DE use of wire welded underneath (most common), springs, rings or bushes to make the opening fixed. Openings from 2 mm until 50 mm. In this way, the drain of the belt varies from 20 to 90 per cent. The diameter of the wire links can vary from 1.6 millimeters for very light or fine meshed belts to 4 millimeters for heavy-duty applications.

Furthermore the belts can easily provided with carriers, flights, product carriers, high side plates or additional rollers. Belt can be made in a self-supporting execution too. Minimal drain openings of about 0,7 millimeters can be realized by flattening the wire links. The space between the links is then smaller than the diameter of the link itself.

The Wire Link Conveyor Belt 1 is the version with lamebrain or welded edges. The belt edges are generally formed by two ore more rows of plate links. The wire links and plate links are assembled on the cross rod which is fitted on both sides with a welded ring or a butted head.

The Wire Link Conveyor Belt 2 is the version with chain edges. The belt edges are formed by a hollow pin chain. The links and chains are assembled on the cross rod which is fitted on both sides with a welded ring. The chain is mostly kept in place by welding a ring to the outside as well as to the inside of the chain. If the ends of the cross rods are narrowed, the inside of the chain is secured by this narrowing and the inner ring is canceled.

The Wire Link Conveyor Belt 3 is the version with roller edges. The belt edges are formed by two rows of plate links with a roller in between. The wire links, the plate links and the rollers are assembled on a cross rod fitted with a welded ring.

Wire link belts can be used at conveyor speeds varying between less than 1 metre per minute and 50 meters per minute, depending on the processing situation and the intended working time. The strength of the belt and, to some extent, its ability to resist wear, are determined by the number of plate links and, if present, the chain on the edges. In the belt full plate links are mounted every 250 to 400 millimeters. The belt support can be placed underneath these plate links. In some cases the belts can also be provided with plate links in an eccentric version, which provides additional wear resistance.

Wire link belts are used in production processes having temperatures from -100ºC to +600ºC.

Wire link belts are made of thin round wires with an eyelet on both sides, to which they are hinged by means of a pin. In this way, a thin one-layer belt is created with the following advantages:

-It is impossible for a product to form a deposit in ‘hollow spaces’ in the belt, which are difficult to reach. -The weight of the belt can be kept relatively low. -Process fluids and gasses can go easily through the belt -The belt is easy to clean. -The belt is positively driven by means of sprockets or driving drum. So there is no belt slip and it is possible to use relatively small diameters. This all adds to a perfect belt run without steering problems. -The belt is easy to repair.

wire link processing belts are used in e.g.

• Freezing units -Foundries -Quench tanks -Dehydration Units -Pasteurizers -Drying Units -Steel blast units -Sieving Units

• Sterilizers

• Washing Machines

• Packing Machines

• Baking Ovens

• Cooling Systems

• Blanch-in Units

• Storage units

• Assemblage-install.

• Shrinkage Units

• Others

Previous

Next

Previous

Next

Product inquiry

We will contact you within one working day. Please pay attention to your email.